|

|

#11

|

|||||

|

|||||

|

Quote:

Steve and Myka pretty much covered what I was pointing out Point loading the concrete floor will break it By placing a larger foot of something that won't break under the load, you're spreading the weight out over a larger area, thus putting less stress on a smaller area of the concrete And ya, the wood he has there under the post will collapse under load Have you ever hammered any soft wood ? It compresses very easily His wood will compress and/or split |

|

#12

|

|||||

|

|||||

|

Quote:

Last edited by Myka; 07-21-2013 at 02:47 AM. |

|

#13

|

|||||

|

|||||

|

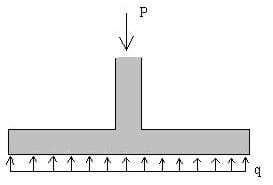

Just an example of spreading out a load

Figure 7. Bearing pressure on a shallow foundation. Figure 7. Bearing pressure on a shallow foundation. The suggested idea of building a closet is a great plan. Build a load-bearing wall and enclose it to create a storage area. Then the area is not wasted by a jack post Last edited by gregzz4; 07-21-2013 at 02:56 AM. |

|

#14

|

|||||

|

|||||

|

Quote:

Then build a storage room around it |

|

#15

|

||||

|

||||

|

Quote:

Remember a hammer can easily hit with 600 psi. 1/4" steel is not very rigid, it's probably not spreading the weight much farther than an inch past the foot of the pole. His tank and stuff is at max 3200 lbs. Even if 100% of that weight was on the two stands that is only 1600 lbs a leg. That's about 100psi per post on the concrete with just the 4x4 bottom of the post. Even a poor concrete basement is at least 1500psi concrete. And then the fact that the concrete itself is spreading the weight to the earth under it. Unless you built on a swamp or think there might be erosion under the slab. So even if the posts are in a bad spot with only 3" of concrete there still wouldn't be a problem. And remember the squash blocks to the foundation wall are taking probably at least 35% of the weight, And even at a 16' span with the joists those could take another 35% of the weight without blinking.

__________________

-My 330g build thread |

|

#16

|

||||

|

||||

|

Quote:

Building a little closet or a stub wall in the center will be more than enough.

__________________

-My 330g build thread |

|

#17

|

|||||

|

|||||

|

Quote:

Maybe you misunderstood me when I was talking about where to place the 1/4" steel |

|

#18

|

||||

|

||||

|

Quote:

I never said his 2x6 will transfer the weight to the large piece of wood he is using. I simply said the wood and the 1/4" steel would displace the weight to a similar footprint. There will probably be some compression of the 2x6 if that wall is actually taking much weight at all, but once it does a slight turn of the jack will fix that right up. A single stub wall in the center will carry the weight just fine. A closet in that spot would be great too. But at the same time, nothing at all would probably never have an issue too. But a little over engineering is seldom a bad thing.

__________________

-My 330g build thread |

|

#19

|

|||||

|

|||||

|

Quote:

I see a small piece of plywood under his jack post. If it's larger, that would explain me talking about a larger plate of steel If it's a length of 2x6, it's still not sufficient. Either way it will compress and would be better suited with something to spread the load out farther, away from the post, to alleviate any stress on the floor directly under the post I agree with you saying he could just adjust the post as the wood compresses, but that's not a 'safe' method. As I said, the wood could also split, and then the whole thing is useless I'm unclear with your statement; "I simply said the wood and the 1/4" steel would displace the weight to a similar footprint" I was talking about placing a large plate of steel under the jack post to spread out the load. I never mentioned any wood in my idea What do you mean ? |

|

#20

|

|||||

|

|||||

|