|

|

#7

|

|||||

|

|||||

|

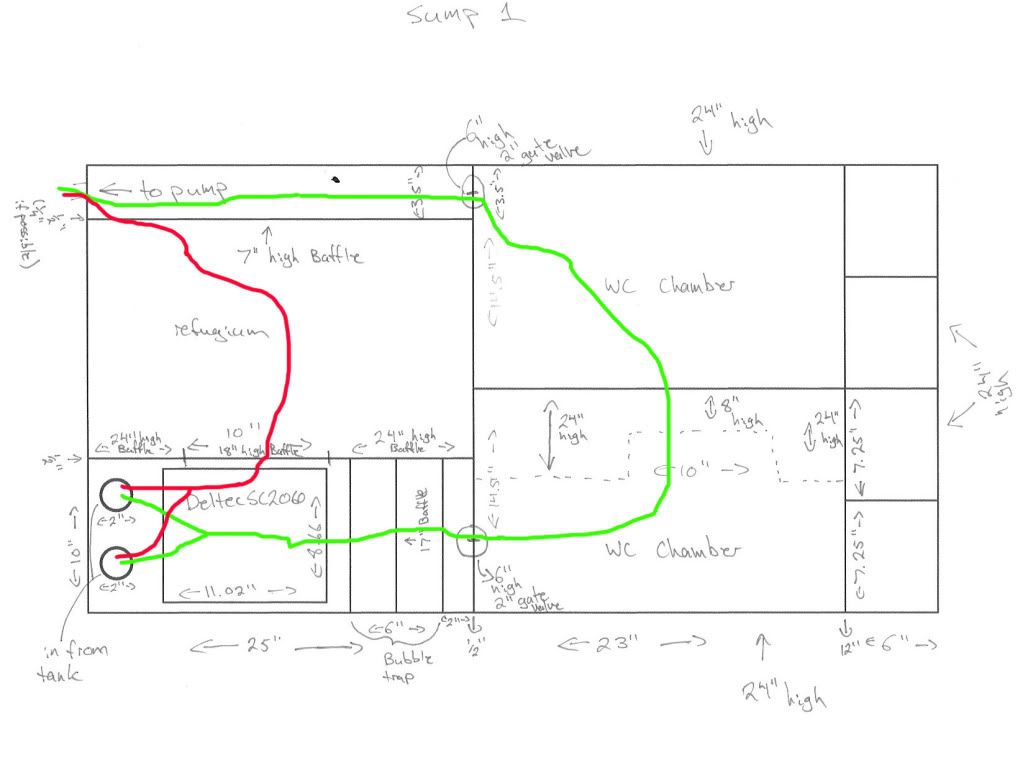

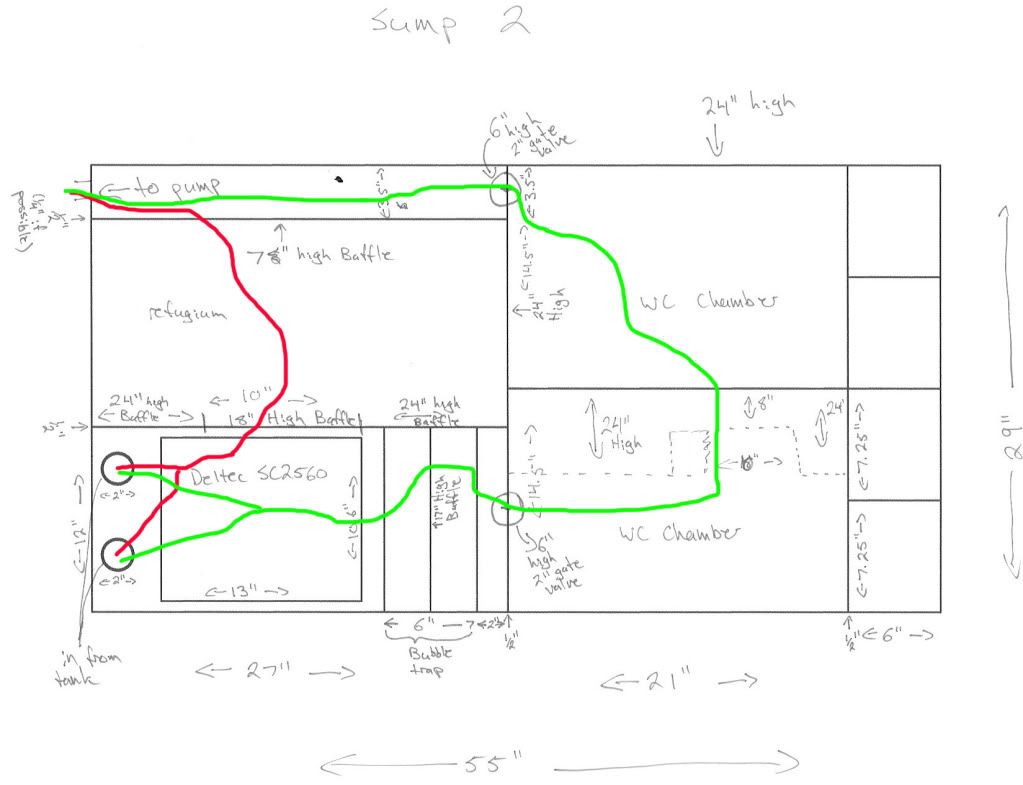

The stand should have been delivered to Red Coral today (woohoo!). The sump needs to go in before the stand is placed on top of it, so I made more formalized drawings before 'taking the plunge' and ordering tomorrow. If anyone has any input in to this design, please, please, PLEASE let me know.

I sat down with the computer and worked out proper 'to scale' drawings of the sump. I've drawn two versions, version 1 will only fit a Deltec SC 2060 skimmer, and version 2 will fit a Deltec SC 2560. Based on manufacturer specs, the 2560 seems like it's a bit of overkill for my size of aquarium, but I like it for 3 reasons: 1. In V2 the water change chamber is smaller (approx 17% of display volume), so at any given moment I'll have less opportunity to change the water. If that is the case I want to have maximum nutrient export methods possible. I can still do larger, manual water changes, but the point of this tank is to build something that doesn't require me to get my hands wet (though I know I will cuz I love getting my hands wet), so I want to only use the water change chamber to do my water changes. 2. The SC2560 is the smallest size you can have the Deltec auto-cleaner for their skimmer. I won't get one right away, but I love the idea and I want one eventually. 3. Even if I get an SC 2060, I have extra space for a later upgrade (though for how expensive those things are, I will need to start playing the lottery if I'm thinking about 'upgrading'). The other thing I did on both versions that I need some input on to know if it's possible: In my first design I was afraid that water wouldn't flow through the entire sump, leaving dead spots in the water change chamber (on the right), so I added a central baffle that will force water to flow more in a true 'U' shape. At first I had it so that the baffle had a cut out so that water flowed over the cut out section, but then I realized that I would be creating a dam that would prevent me from being able to completely drain the water change chamber with one pump. I hope that instead I can have that baffle flipped upside down. I drew it on the plans so I hope you see what I mean. I made the bubble trap section exactly 6 inches wide (total width), which is what I've heard is the standard width for a bubble trap. I don't know how thick the glass needs to be so I really just drew it in as a place holder. I want the water height in the sump to be 17 inches when the sump is running, so I made the middle baffle of the bubble trap be 17" high, I might need it to be 16.5" high, not sure yet. I also left a full 2 inches between the final bubble trap baffle and the baffle that separates the water change chamber and the skimmer/refugium chamber. If I can get away with less that 2 inches let me know as that would give me more space between the drains from the tank and the skimmer. The other thing I added was a 3.5 inch wide trough between the entrance to the refugium and the exit from the water change chamber. It's only 7 inches high because I don't want to completely isolate the refugium, but it will keep the most forceful stream of water from directly hitting the regium. If anyone thinks this trough needs to be wider let me know, but I would like to keep it as narrow as humanly possible so that the refugium can be as large as possible (this is part of my desire to have as much nutrient export as possible so that a smaller water change chamber isn't such a big deal). I have also looked up the various reactors I think I'd want. The biggest reactor (the ones that could hold zeovit or biopellets) should be able to sit on the floor to the left of the sump, since I'm leaving 12 inches of space between the sump and one side of the cabinet, and the return pump is only about 12 inches long. At the moment I think I'd at most want two other reactors (3 total), and since I'd be using them for things like activated carbon and a phosphate absorber, they can be the large size TLF reactos that can hang off the side of the sump in the refugium chamber. At best, I need no reactors in the water change chamber. At worst, I need one reactor in the water change chamber, but I would put its pump and output on the other side of the central baffle so that even when I drained the water change chamber, it would remain on, full of water, and never be affected by the water change. This will also leave me the option to add a calcium reactor one day if I wanted (I think) The one thing I didn't account for was how thick the the baffle between the two sides of the water chamber are. If it needs to be half inch thick, then each half of the water change chamber will be either 14"x23" (sump 1) or 14"X21" (sump 2). As before, the green line shows the flow of water when the gate valves are open, the red line shows the flow of water when the gate valves are closed. Sump option 1 (skimmmer Deltec SC 2060)  Sump Option 2 (skimmer Deltec SC 2560)  Last edited by asylumdown; 05-27-2011 at 06:03 AM. |