|

|

#1

|

|||||

|

|||||

|

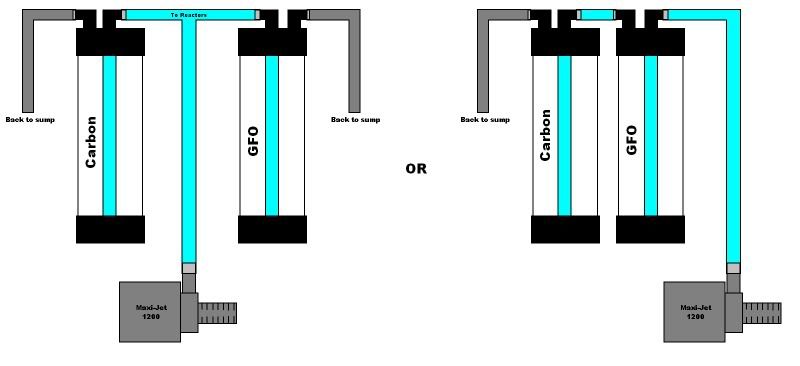

Who uses which method and why? I have typically done the setup on the left, using seperate water flow through both reactors.

Is it more beneficial to 'daisey chain' them together and have the water flow from one reactor to the other? EXAMPLE

__________________

They call it addiction for a reason... |

|

#2

|

|||||

|

|||||

|

I always thought they were put in series to have better control over the tumble rate.

For the left example... If either the carbon or GFO chamber is plugged faster, the flow will increase in the other chamber, causing an undesirable tumble rate. For the right example... The whole system slows down and it's just time to change the media. That being said, I'm not sure what pressure the TLF reactors can handle, so that might be a consideration as well. |

|

#3

|

|||||

|

|||||

|

I'm just about to plumb a 2nd TLF as well. I'm currently running Rowaphos but will be doing GFO and carbon.

From what I've heard, the setup on the right will tend to clog up the carbon faster. Not sure why but someone said that if you have the GFO tumbling too quickly it will degrade and move to the carbon TLF. Not hi-jacking but what pump do you use? This may affect the result as well. I'm leaning towards the setup on the left. |

|

#4

|

|||||

|

|||||

|

I use a maxi-jet 1200 with the two supplied ball valves from TLF to control flow with the left setup running.

With the setup on the right, you could obviously swap the carbon and the GFO so that it goes into the carbon chamber first. Would it even make a difference if the carbon or GFO was first? (other than the breakdown of the GFO if it tumbling too fast).

__________________

They call it addiction for a reason... |

|

#5

|

||||

|

||||

|

I use the setup on the right with mine. I run carbon first gfo 2nd, I get a decent tumble on the carbon, and a slower flow through the gfo. When I notice everything slowing down I usually know its time to change the carbon. I will also test the phosphate level coming out of the reactor to determine if it's time to change both.

|

|

#6

|

|||||

|

|||||

|

I use the layout on the left. But, I have three ball valves on the system to control the flow. I have one ball valve between the "T" and each reactor. The third is between the pump and the "T".

|

|

#7

|

|||||

|

|||||

|

Quote:

Correct me if I am wrong, but, I don't think you want your carbon to tumble at all. It should be held tight to prevent any tumbling because the particles are known to cause HLLE in Tangs. I have a dual BRS unit. GFO first, then carbon. The problem is the carbon starts clumping and will slow down the flow. You just need to keep adjusting the valve to increase the flow quite frequently. This would hold true for option 2. I would think the 1st option may be best. You can control the flow to each reactor then and not have to worry about how one affects the other. Not sure though if one begins clumping and causing some backflow, if it would increase the flow in the other reactor though. I would think it should be fine but just something to look out for. Ideally, running a pump on each reactor is the best because it would be a better case of setting it and forgetting it. Although, this method costs more and is less energy efficient.... |

|

#8

|

||||

|

||||

|

Yes you are right. I should have clarified, by tumble I meant I have enough flow in the carbon reactor to lift it about 3/4 of an inch off the bottom, of the reactor. Where the water "comes through" the carbon there is a slight tumble. On the whole there is very little tumble, and next to no "tumble" in the gfo.

|

|

#9

|

|||||

|

|||||

|

Yeah I actually have a seperate pump for each one. I just plumbed them together the other day to have less tubing everywhere. I wonder if I should go back to the regular setup, or even plumb them individually from my return pump.

When I plumb my new system, these will be running off a manifold from my return pump, so I will plumb them all seperate I think.

__________________

They call it addiction for a reason... |

|

#10

|

|||||

|

|||||

|

The more I do research the more I think I may go this route as well. Might just need a bigger return pump.

|