|

|

|

|

#1

|

||||

|

||||

|

Quote:

Quote:

Hope you are right haha. It will be slow and steady sort of a build I hope. I am doing this in my townhouse garage, so it is cold in there now. I cant spend as much time as I would have during the summer. May have to fire up a heater to extend some work hours. With garage getting cold, I may only have 6 months timeframe to run QT tanks as well, as I am not sure if heaters will be able to keep water at correct temp when garage will be at like 0C during winter. Last edited by cvrle1; 11-07-2019 at 03:18 AM. |

|

#2

|

|||||

|

|||||

|

Quote:

__________________

Current System 75 Gal with 30 Gal Sump Reef Past Tanks 60 Gallon True Cube 30 Gallon Breeder 165 Eurobraced Starfire Custom 10 Gallon Softy Tank(My First Tank) |

|

#3

|

||||

|

||||

|

In all honesty I think it may be a blessing in disguise, as it will force me to take things slow, and not add a lot all at once. It would give me 6 months or so after putting things in to leave it be, monitor and see how things go before I can add more.Of course that is just in my head, and when push comes to shove it may all go down the drain and I run QT tanks 365 days a year

|

|

#4

|

|||||

|

|||||

|

Quote:

If you can be that patient then you have one up from me. I'm not as patient haha. Where there is a will there is a way I say.

__________________

Current System 75 Gal with 30 Gal Sump Reef Past Tanks 60 Gallon True Cube 30 Gallon Breeder 165 Eurobraced Starfire Custom 10 Gallon Softy Tank(My First Tank) |

|

#5

|

|||||

|

|||||

|

Hello

Wow truly amazing on the sanding and polishing bit. Good work. Titus

__________________

A link to http://www.yahoo.com |

|

#6

|

||||

|

||||

|

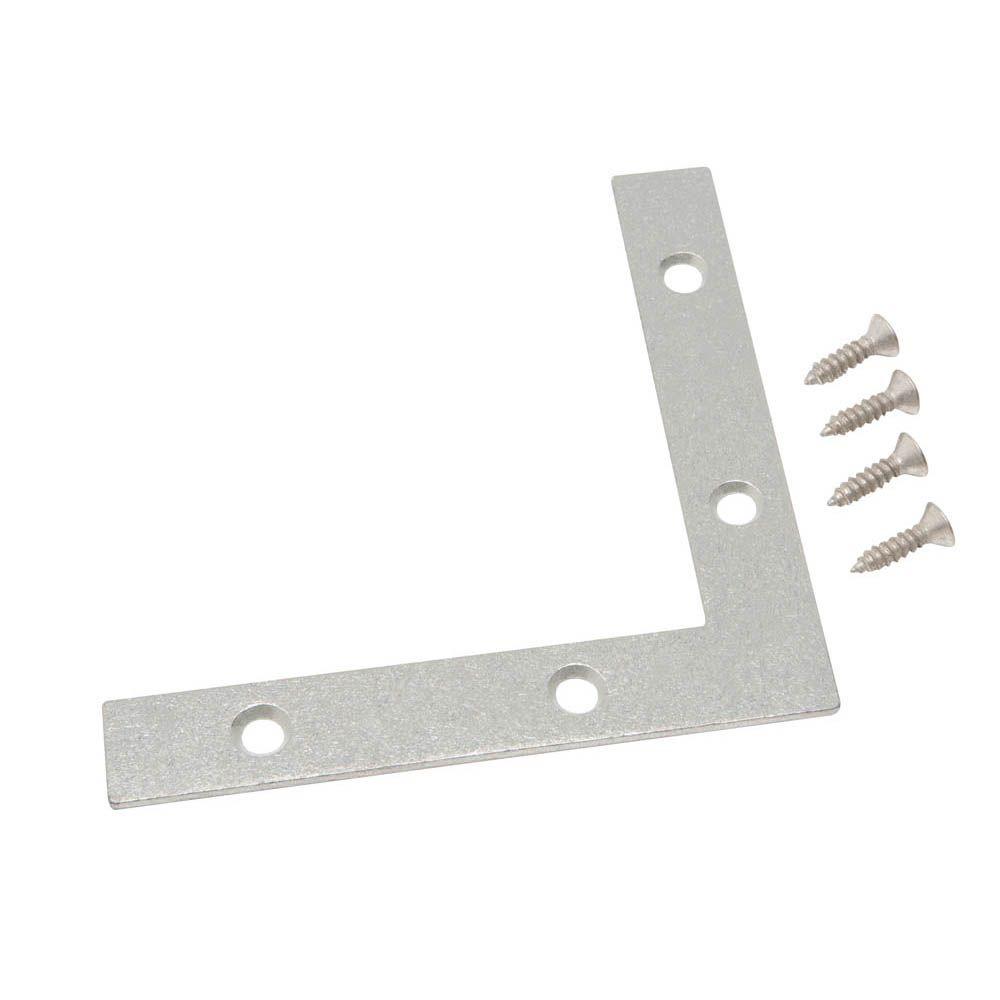

I started working on light mount for the Noopsyche K7 Pro IIs that I will be using. I bought aluminum square tubing for this build. I cut tubing at 45 degree angles and used flat corner braces to connect it all together.

Unfortunately few cuts werent perfect, so there is a gap between the 2 pieces when I connected them. I wanted to make sure that my angles were a perfect 90 degrees.   Not a huge deal as I will use aluminum rods and braze it to fill in the gaps. Once it is primed and painted it shouldnt be visible. I also put 5 pieces of flat aluminum across. This will be used as light mounts.  Finished mount, for now   I actually plan on making this whole thing have adjustable height. I have a plan in my head, so we'll see if it works out. Should be pretty simple to do, so will update once I have more in next few days. |

|

#7

|

|||||

|

|||||

|

Clean construction

__________________

Current System 75 Gal with 30 Gal Sump Reef Past Tanks 60 Gallon True Cube 30 Gallon Breeder 165 Eurobraced Starfire Custom 10 Gallon Softy Tank(My First Tank) |

|

#8

|

|||||

|

|||||

|

Hello

Quote:

Quote:

Titus

__________________

A link to http://www.yahoo.com |