|

|

#11

|

|||||

|

|||||

|

Did some re-working of my sump last weekend. Two things about my sump have bothered me from almost day 1.

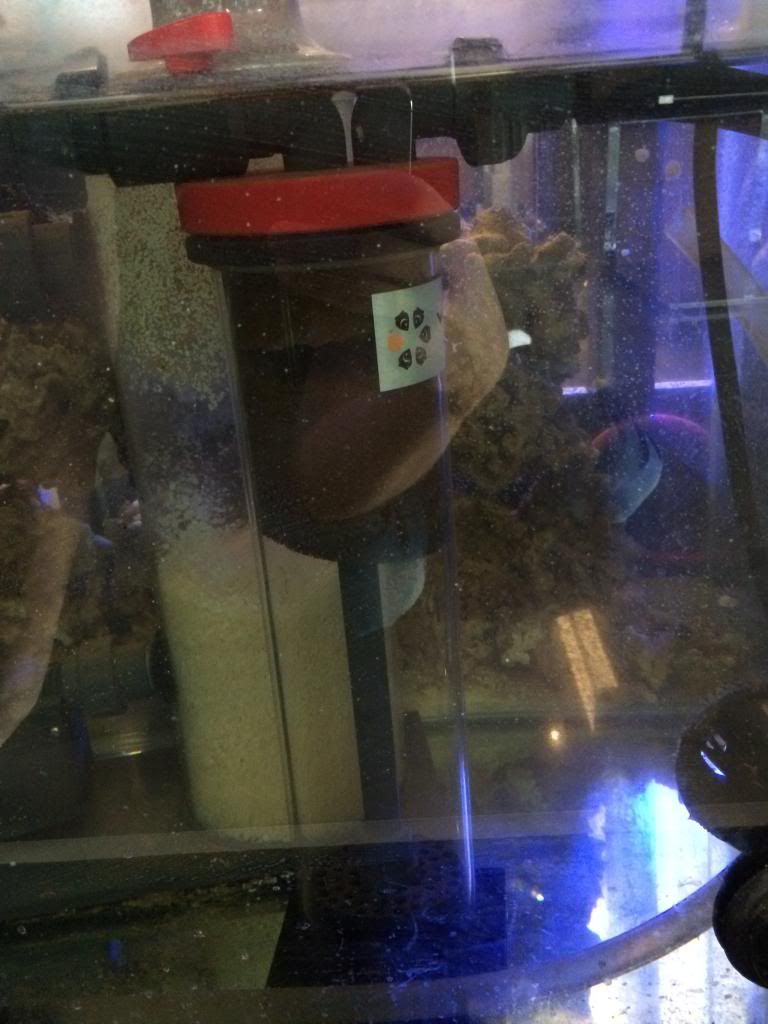

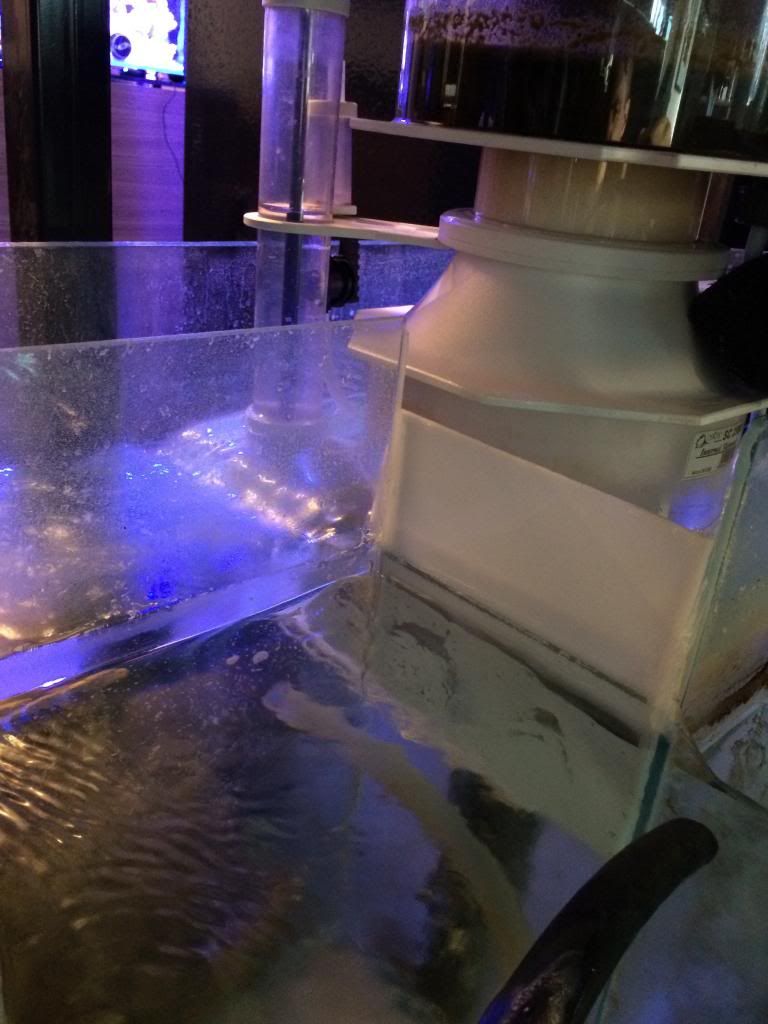

1 - I have too many things that require pumps and power in my sump. The only place to put them is the water change chamber mostly, which makes it cluttered and takes up volume. 2 - My sump is a micro-bubble factory. It's U shaped, as in to say water entered and exits the sump on the same side, but since going back to regular durso style overflows I have come to realize that my design allows for a fair amount of water to basically bypass the entire sump, which doesn't give the microbubbles from the overflow time to rise and pop. Unfortunately I don't have many pictures of how it used to be, but the changes were thus: I previously had one pump running my GFO reactor, and a separate pump whose sole purpose was to drain water from my sump for water changes. The GFO reactor pump was VASTLY over-powered for the amount of flow I needed, and the other pump, which wasn't as powerful was taking up a lot of space for only ever getting turned on for 6 minutes every 10 days. I got rid of the over-powered GFO pump and through some fancy plumbing, set up my water change pump to have more than one function   I t'd the line coming off the water change pump that previously went straight to a drain to the sewer, so that when the valve you see there is closed, water flows in to the reactor. When I'm doing water changes, I close the valve on the top of the reactor, and open the valve to the sewer and that pump drains my sump. Since a failure here would obviously be catastrophic, there's a second gate valve further along the pipe closer to the sewer drain, so two gate valves would need to fail for that pump to start draining my tank. I also put the first gate valve well below the water line, because the line is under some pressure from the reactor flow being throttled. This way if there is a failure in my hoses the pump won't go spraying water all over the inside of my cabinet. I also took a piece of acrylic and siliconed it to one of the exits from my skimmer chamber. Previously, water leaving the skimmer chamber was split by a bulkhead, with half flowing in to a skinny and long 'frag chamber' (though I've only ever used it as a cryptic refugium filled with live rock and sponges), and half flowing in to the large water change chamber. The water that went directly in to the water change chamber could then make a quick 90 degree turn and flow in to the return chamber, taking all sorts of micro bubbles with it. I don't remember my logic for thinking that the 'frag' chamber couldn't handle 100% of the flow of the sump, but with this acrylic piece in place, water now is forced to make the full journey from one of the the sump to the other.  Before I had to run filter socks, or my tank was a micro bubble mess. Now without filter socks, there's about as many micro-bubbles as there were with a fresh sock on the tank before. With filter socks, there's now zero micro bubbles. And even though very little has changed because I chopped so much stuff back, some gratuitous full tank shots because I can   |