|

|

||||||||

| Portal | PhotoPost Gallery | Register | Blogs | FAQ | Members List | Calendar | Search | Today's Posts | Mark Forums Read |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||||

|

|||||

|

This thread is going to happen in semi-slow motion, mostly because the build of the tank is tied to the build of my house, which, as I'm sure you can guess, happens at the pace it happens.

I want to start off by giving the specs, and posting the pictures I have so far. The tank will be 6ft long X 34inches wide X 26 inches high for a total display volume of approximately 275 gallons. It's being built right in to the house as a divider between two rooms, the dining room and the office, so it will be open on two sides. I don't have a fish room in this house (some battles you have to 'compromise' on in marriage I suppose), so 99% of the equipment will be under the stand, with the only remote equipment being an R/O storage container in the basement below the tank. The goal: To minimize the amount of manual labour required to maintain the tank. Since it's getting built right in to the house, I had an awesome opportunity to automate water changes as much as humanly possible, and the wall space the tank sits in has been plumbed with a water supply, a drain to the sewer, and an emergency floor drain under the aquarium. Here's the space the tank will occupy (viewed from the dining room):  Closer image  Water supply and drain  Power supply  Emergency floor drain  View of tank from office (looking in to dining room and kitchen)  Still working out the details of the sump with Kevin at Red Coral, but it will be designed so that one half of it can be isolated from the tank, drained, filled with fresh R/O water, mixed with salt, and then returned to the main system without ever needing to hand bail a bucket, or siphon a single drop. I'll post more pics/drawings as it progresses. |

|

#2

|

|||||

|

|||||

|

Looking good. I love 2 side viewable tanks.

|

|

#3

|

||||

|

||||

|

nice, i wish i can build a tank into the house like that. Maybe my next house lol. Can't wait to see how it comes together

__________________

155 gallon bow front |

|

#4

|

|||||

|

|||||

|

I'm pretty excited. There's still some open questions about the tank, most notably how I'm going to light it (it's so wide!), but those will be answered when we get there. The next thing to take care of will be the sump.

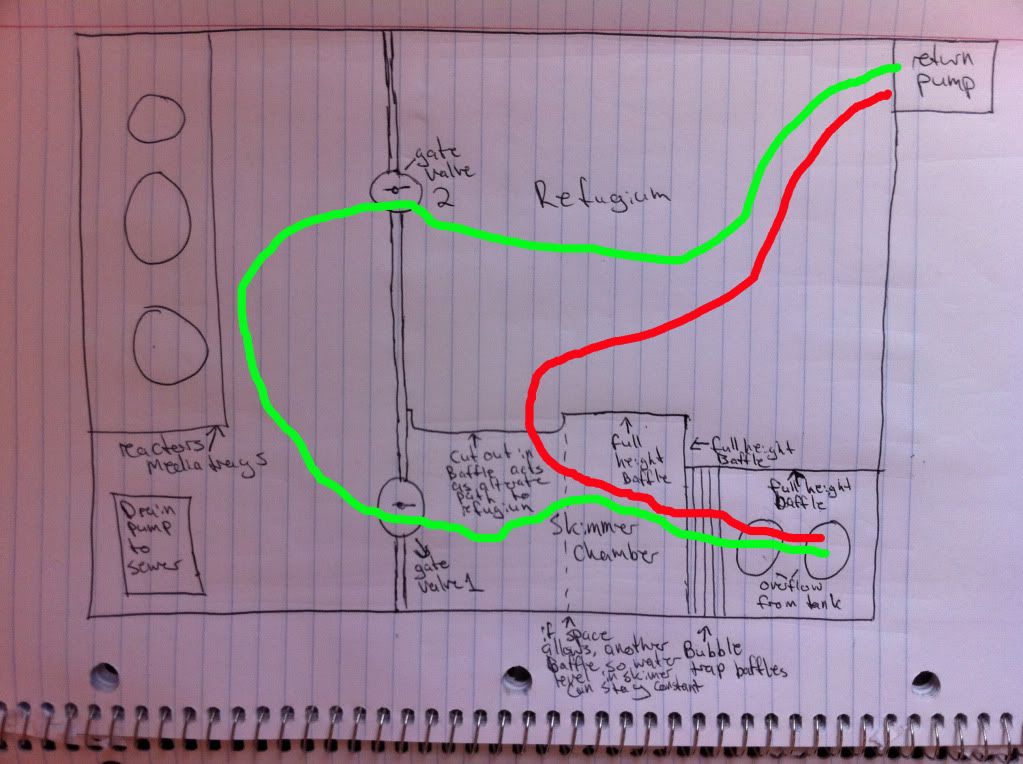

The metal stand is being custom built to be a total of 40 inches in height, with 2 inch steel beams. That gives me a 'usable' footprint of 68 X 30 inches of floor space under the cabinet. I want the biggest sump possible, so assuming I need a half inch of clearance between the base of the stand front to back, and 12 inches of open space on the long ends for any equipment that can't be in the sump itself, the sump will be 56X29 inches long. I also want the sump to hold as much water as possible, I want the sump to hold as much water as possible so if I make the sump 20 inches tall, I can keep the water at 12 inches when the sump is running without risking overflowing the sump when the tank loses power. When the aquarium is turned off, I should have roughly two inches between the top of the water and the lip of the sump tank. Here is my crude first draft for what the sump will look like. There's going to be two compartments, and the water will flow in a U shape from the point it enters, to the point it exits the sump (green line). I'll be able to turn the gate valves in the middle of the sump isolating one half of it from the tank, with an alternate route for the water when the gate valve is closed (red line). That will allow me to pump all the water out of one half, fill it back up with fresh water, add salt, mix, then re-open the gate valves returning the new salt water to the main system.  I'm trying to decide what skimmer I can fit under that cabinet (it will likely need to be on a 2.5 inch stand) so I can work out exactly what I need in terms of space in all the compartments. |

|

#5

|

|||||

|

|||||

|

Looks good man.....envious.......very envious

a) could go with 12 bulbs of HOT5(that should fit in there just right(depending on the unit I suppose, Im running TEKs and they will fit)).....either two six foot units(TEK doesnt make a sixer) or four three foot units.........or b) something like three 250w MHs with Lumenmax Elite reflectors and some kind of strip lighting on the sides for blue supplementation(either T5 or LED)........or c).....go with LEDs which I admittedly know nothing about, so someone else will have to chine in here Im sure you'll get it figured out........guess it's all gonna depend on what you wanna do with the tank.....and depend on your budget

__________________

260g mixed reef, 105g sump, water blaster 7000 return, Bubble King SM 300 skimmer, Aqua Controller Jr, 4 radions, 3 Tunze 6055s,1 tunze 6065, 2 Vortech MP40s, Vortech MP20, Tunze ATO, GHL SA2 doser, 2 TLF reactors (1 carbon, 1 rowa). http://www.canreef.com/vbulletin/showthread.php?t=50034 . Tank Video here http://www.vimeo.com/2304609 and here http://www.vimeo.com/16591694 |

|

#6

|

|||||

|

|||||

|

I think I'll probably go with the MH lights. The builder still needs to put in the ventilation to the outside, but the drawings call for one side of the wall above the tank (the office side) to be vented screen doors so I think I should be able to deal with the heat. When it's done, it will look like a solid floor to ceiling wall with a tank in the middle from the dining room (with two small, hopefully invisible access panels so I can clean the glass) with all the doors and stuff on the office side.

I'll check out those reflectors, I was nervous 250 watt lights wouldn't cast a wide enough footprint for such a wide tank, but with supplementary PC lighting on the sides it should be enough. |

|

#7

|

|||||

|

|||||

|

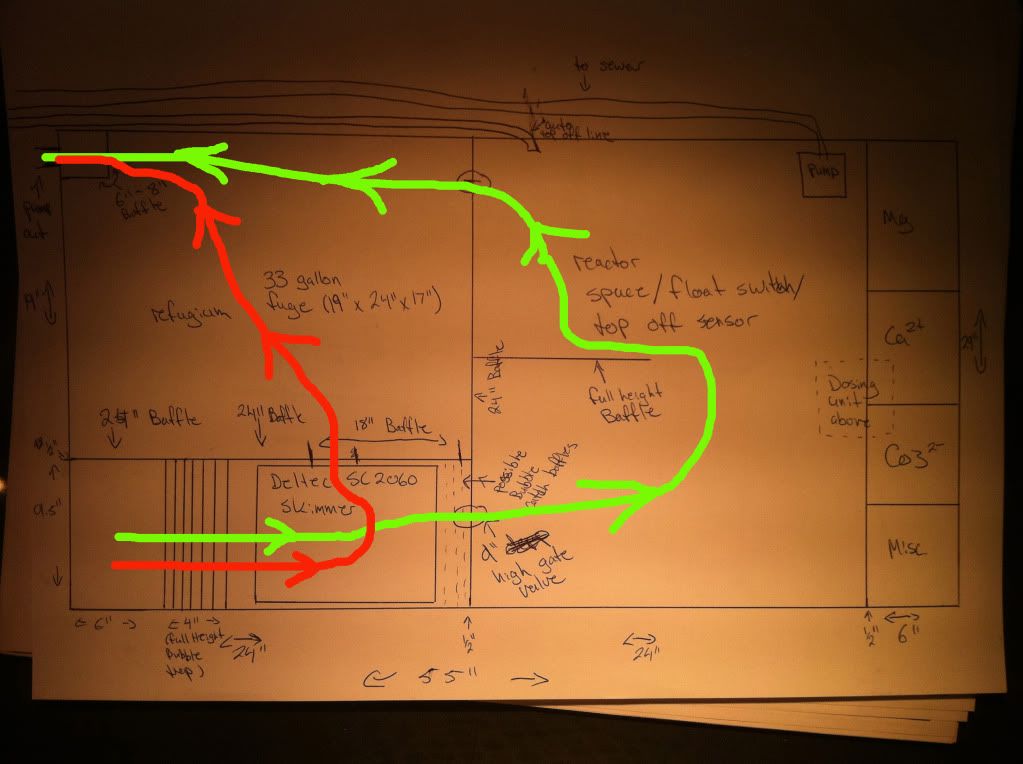

I sat down tonight and re-worked the sump drawing a little and actually drew it to scale.

I want the Deltec SC 2060 skimmer for this tank, which is 23.62 inches high (they say that includes an extra half inch for clearance), so if that happens, I can do this: Make the sump 55" long X 29" wide X 24" tall. Taking in to account the 2 inch steel beams supporting the stand, that still gives me about a foot of floor space left over in the cabinet. 6" of that will be separated by a full height baffle and turned in to 4 dosing chambers which should be able to hold about 4 gallons of fluid each. They'll be separated from the sump by a half inch baffle. This will make the sump area 48.5"LX29"WX24"H. By making the sump 24" high, I can up the height of the water level in the sump from 12" like I had originally planned to 17", that will still give me 7" of space between the top of the water level and the rim of the sump, which is more than enough to cope with the extra water volume in a power failure. By keeping the water level at 17 inches while the power is running, the sump will hold 103.5 gallons of water during normal operation, with a total capacity for 146 gallons when the power is off. I will need to put the skimmer on an 8 inch stand, but that will still give me almost 8 and a half inches of head room between the top of the skimmer cup and the bottom of the aquarium. If I divide the sump perfectly in two, each half will hold about 50 gallons of water when the aquarium is running, which gets me almost exactly where I want for my water change system, as I want to be able to do at least a 50 gallon water change at once if I so desire. So, assuming there's a half inch baffle between the two halves, that gives me 24X 29 inches on either side. I've given myself a 6x9.5 inch compartment for the drains from the tank. Hopefully that's big enough for two output pipes with enough room left over for me to change filter socks. I then left a 4 inch space for bubble trap baffles. I'm not sure if that's enough room for a bubble trap, I'll be getting Kevin's input on that. Then there is the skimmer chamber, it's just enough to get the skimmer in with a bit of clearance on either side. If this is too tight, I can cheat the centre baffle a couple of inches to the right and make the reactor/water change chamber a little smaller, or cheat the baffle that separates the skimmer chamber/input chamber out in to the refugium section, or both. I added a baffle that cuts in to the middle of the reactor/water change section to encourage water to flow more in a U shape, as I don't want there to be any dead spaces in the corners. I'm not sure if it's necessary, or if it will make it hard to put in reactors so it might not be necessary. I also am not sure if this sump will allow micro-bubbles in to the display, so I added a possible space for another bubble catcher baffle set after the skimmer. It might not be practical to put one there, but if not there, I don't know where else! Since I'll keep the water level at 17 inches high when it's running, I made the baffle between the input/skimmer chambers and the refugium be full height, except for a stretch right before the centre dividing baffle. There the baffle height between the skimmer chamber and the refugium drops to 18 inches (or maybe even 17.5) so that when the first gate valve is closed, the water in the chamber only has to go up by one (or half) an inch before it pours over in to the refugium, diverting flow away from the reacto/water change chamber. With such a small rise in water level, the skimmer will hopefully not go nuts when I divert the water directly to the refugium, and the water level in the refugium won't fall very much before more water stars pouring in to it. Once everything has reached equilibrium again, I will close the second gate valve, completely isolating the reactor/water change chamber from the system. Green line is water flow when the gate valves are open, the red line is when the gate valves are closed. I also flipped it so that the external pump is on the side of the cabinet with the drain (where the RO unit will be), and the top off reservoirs will be right up against the side with the power supply. It will mean that the auto-top off line and the drain line will need to traverse the whole length of the sump, but since I'm only leaving 12 inches of space it lets me keep that 12 inches all on one side (the side with the R/O unit and external pump). It also means that the R/O unit won't have to be suspended above the dosing chambers, as I think that would make it hard to re-fill them. I'm very open to suggestions, comments, or improvements. The sump will need to be ordered soon as it needs to go in before the stand, and they need the stand in place shortly after they start drywalling.  |

|

#8

|

|||||

|

|||||

|

I just read a study of the lumenmax and lumenmax elite reflectors, it seems like the elite version concentrate light more and the straight lumenmax spreads it out more. I guess it's the balancing act, but I like having concentrated light. Do you think I could get away with the elite one if I supplemented 10-14K T5's on either side?

|

|

#9

|

|||||

|

|||||

|

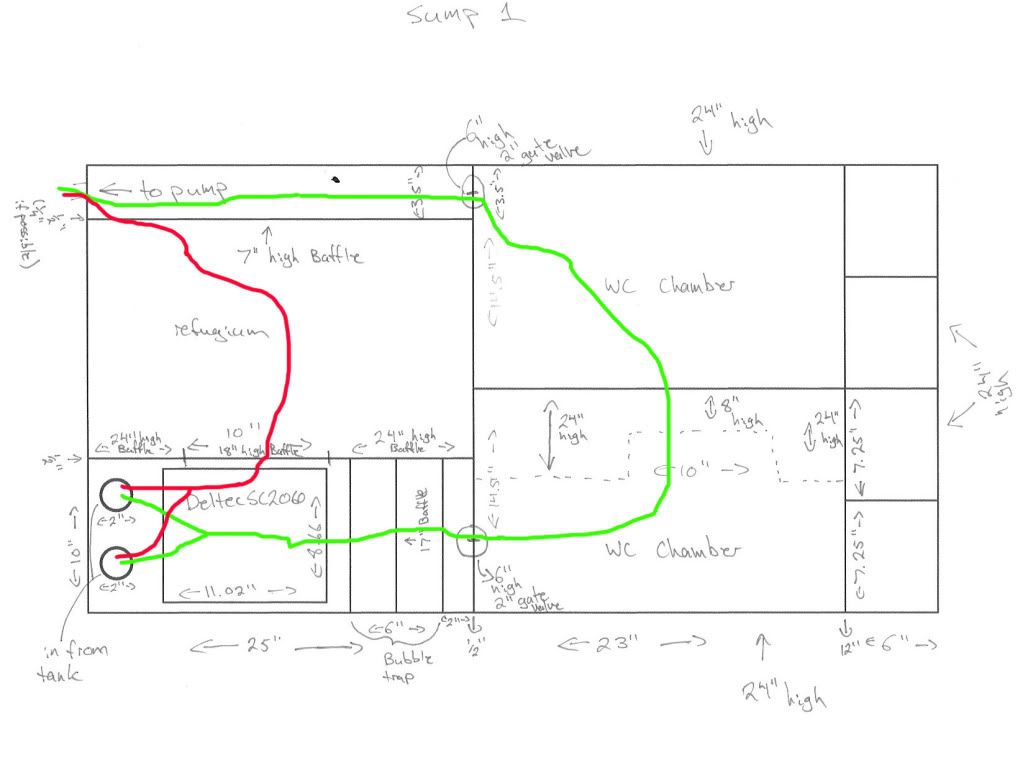

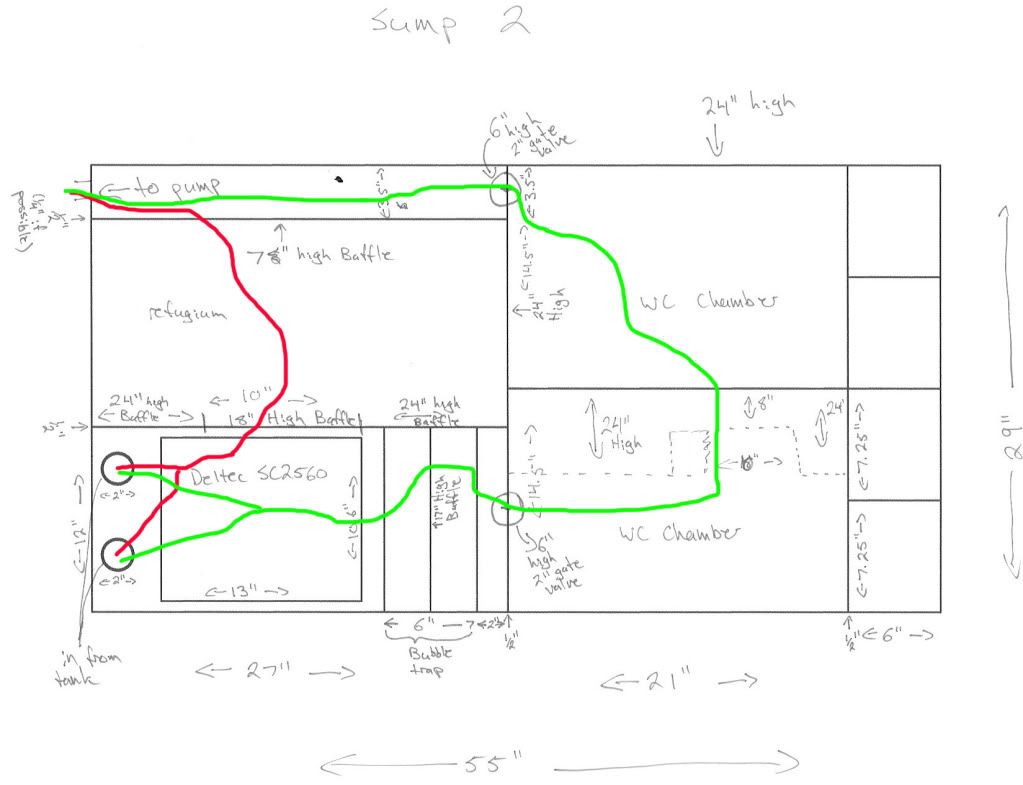

The stand should have been delivered to Red Coral today (woohoo!). The sump needs to go in before the stand is placed on top of it, so I made more formalized drawings before 'taking the plunge' and ordering tomorrow. If anyone has any input in to this design, please, please, PLEASE let me know.

I sat down with the computer and worked out proper 'to scale' drawings of the sump. I've drawn two versions, version 1 will only fit a Deltec SC 2060 skimmer, and version 2 will fit a Deltec SC 2560. Based on manufacturer specs, the 2560 seems like it's a bit of overkill for my size of aquarium, but I like it for 3 reasons: 1. In V2 the water change chamber is smaller (approx 17% of display volume), so at any given moment I'll have less opportunity to change the water. If that is the case I want to have maximum nutrient export methods possible. I can still do larger, manual water changes, but the point of this tank is to build something that doesn't require me to get my hands wet (though I know I will cuz I love getting my hands wet), so I want to only use the water change chamber to do my water changes. 2. The SC2560 is the smallest size you can have the Deltec auto-cleaner for their skimmer. I won't get one right away, but I love the idea and I want one eventually. 3. Even if I get an SC 2060, I have extra space for a later upgrade (though for how expensive those things are, I will need to start playing the lottery if I'm thinking about 'upgrading'). The other thing I did on both versions that I need some input on to know if it's possible: In my first design I was afraid that water wouldn't flow through the entire sump, leaving dead spots in the water change chamber (on the right), so I added a central baffle that will force water to flow more in a true 'U' shape. At first I had it so that the baffle had a cut out so that water flowed over the cut out section, but then I realized that I would be creating a dam that would prevent me from being able to completely drain the water change chamber with one pump. I hope that instead I can have that baffle flipped upside down. I drew it on the plans so I hope you see what I mean. I made the bubble trap section exactly 6 inches wide (total width), which is what I've heard is the standard width for a bubble trap. I don't know how thick the glass needs to be so I really just drew it in as a place holder. I want the water height in the sump to be 17 inches when the sump is running, so I made the middle baffle of the bubble trap be 17" high, I might need it to be 16.5" high, not sure yet. I also left a full 2 inches between the final bubble trap baffle and the baffle that separates the water change chamber and the skimmer/refugium chamber. If I can get away with less that 2 inches let me know as that would give me more space between the drains from the tank and the skimmer. The other thing I added was a 3.5 inch wide trough between the entrance to the refugium and the exit from the water change chamber. It's only 7 inches high because I don't want to completely isolate the refugium, but it will keep the most forceful stream of water from directly hitting the regium. If anyone thinks this trough needs to be wider let me know, but I would like to keep it as narrow as humanly possible so that the refugium can be as large as possible (this is part of my desire to have as much nutrient export as possible so that a smaller water change chamber isn't such a big deal). I have also looked up the various reactors I think I'd want. The biggest reactor (the ones that could hold zeovit or biopellets) should be able to sit on the floor to the left of the sump, since I'm leaving 12 inches of space between the sump and one side of the cabinet, and the return pump is only about 12 inches long. At the moment I think I'd at most want two other reactors (3 total), and since I'd be using them for things like activated carbon and a phosphate absorber, they can be the large size TLF reactos that can hang off the side of the sump in the refugium chamber. At best, I need no reactors in the water change chamber. At worst, I need one reactor in the water change chamber, but I would put its pump and output on the other side of the central baffle so that even when I drained the water change chamber, it would remain on, full of water, and never be affected by the water change. This will also leave me the option to add a calcium reactor one day if I wanted (I think) The one thing I didn't account for was how thick the the baffle between the two sides of the water chamber are. If it needs to be half inch thick, then each half of the water change chamber will be either 14"x23" (sump 1) or 14"X21" (sump 2). As before, the green line shows the flow of water when the gate valves are open, the red line shows the flow of water when the gate valves are closed. Sump option 1 (skimmmer Deltec SC 2060)  Sump Option 2 (skimmer Deltec SC 2560)  Last edited by asylumdown; 05-27-2011 at 05:03 AM. |

|

#10

|

|||||

|

|||||

|

from what i can make out of this design, you may have some major micro bubble issues with it. I am just guessing, but it looks like the refug over flows into the return chamber, if the water level in the return chamber fall below the 7 inches you will have some turbulence right in front off you return pump which is not a good thing. also the bubble trap after the skimmer is not needed from what i can tell, bubble traps are usually used just before the return chamber to control the amount of bubbles getting into the pump, you should only have a baffle after the skimmer to control how high the water level should be in that chamber. hope that makes sense lol but i could also be reading your design wrong too

|

|

| Thread Tools | |

| Display Modes | |

|

|