So, I still don't have my doors painted, lol. We got them to my buddies shop and actually got them primed out with ClawLock. But he got married the weekend after that, and work has been off the wall so they've been hanging in his shop till now.

So a painter friend of mine was doing another kitchen door spray job and has agreed to finish my doors for me. Hopefully I'll get them back by next week and this thing will at least look finished on the outside.

Got home a wee bit early yesterday and was able to get the majority of my plumbing done on my mixing station. On my existing one, I'm not that crazy about the pipe I have filling/mixing the water in the SW tub. It's just a 3/4" line that goes in to about 4" off the bottom of the barrel then has a 45 degree elbow forcing water in a circular motion. It's ok, but no more than that. I found I don't get a whole lot of mixing with the top 1/3 of the barrel. And if I add salt too fast I get a big pile right in the middle of the barrel from the circular motion of the water.

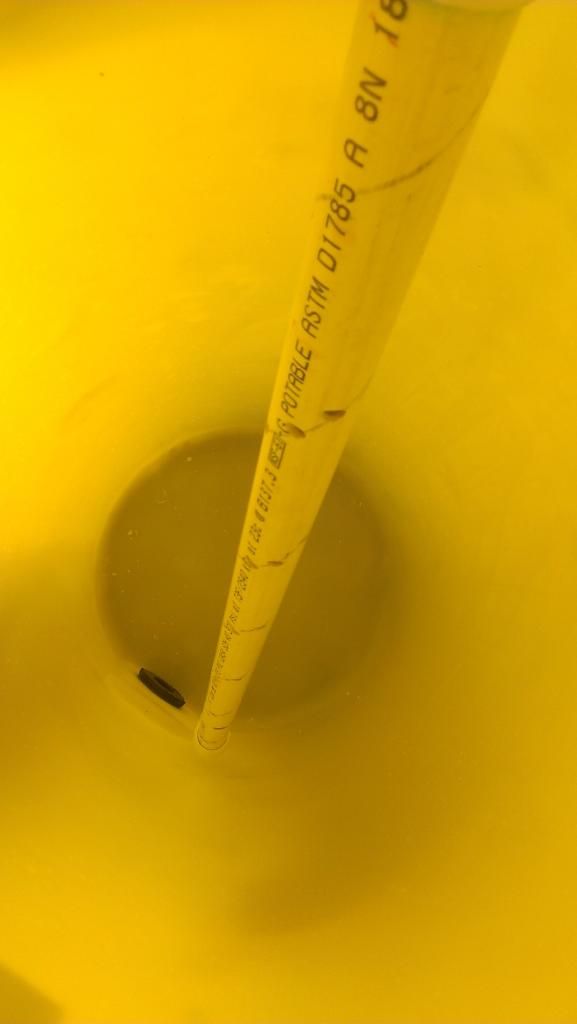

SO.... I figured what I would try on this one is a pipe that goes down to roughly 4" or so from the bottom, again with a 45 degree elbow. Because of the slope of the top of my new barrels, the pipe actually goes from the top left side of the barrel to the bottom right side. I've pointed the elbow back towards the bottom centre of the drum and drilled a bunch of holes in a helical pattern all the way down the pipe. The hope is the water flowing through the holes in the pipe will create tons of turbulence in the barrel and will minimize any piling up of the salt in any one area. Only time will tell I guess

Anyway here's a couple pics of yesterday's adventure.

The helically drilled pipe. I did this on my drill press with the drill bit entering the pipe as far to one side as I could and not on centre. My hope is that this pattern will actually cause the water to spin out of the pipe, in essence creating a bit of a vortex in the barrel. However the angle of the pipe in the barrel, may counteract that effect...so I'm not sure, lol.

The pipe installed in the barrel

The finished product. I have an old Reefflo Dart that I've got hooked up to this thing. I may plug it into my Apex and have it turn on for a half hour a day to keep things aerated a bit. If anyone hasn't read the whole thread, I'll be doing automated, daily water changes via a big dual head dosing pump. Pics are back a few pages. That's what that extra little manifold is on the right side of the setup.