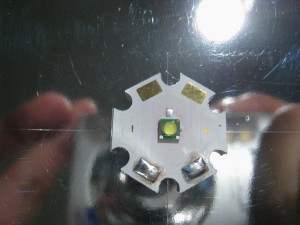

I agree with the others, the soldering connections seem to be the problem. You need to tin the pads of the LED, tin the wire, then solder them together.

Helps a LOT if you have a high wattage soldering iron. You want to heat up the target, not the solder wire. Then touch the solder wire to the target, and let the solder melt onto it.

Careful of the flux (the clear stuff that comes out of the solder wire). If the flux is coating the pad or the wire, then that could be preventing a conductive connection. Don't be afraid to give the wire a good yank after you've soldered it. It should be ROCK SOLID. If it comes off, then obviously the connection was poor.